Figure 1: Ella at UV antifouling test site in North Haven with equipment.

During the summer at AusOcean I had the opportunity to work on two pieces of exciting technology, and work with a vibrant and supportive team. The first technology I worked on was exploring antifouling using ultraviolet light, and the second design project was to design a better Rig mooring system to allow modular use. There are three key effects the internship has had on me that have changed my outlook on my work and life - appreciation for the oceans, how to bring the theoretical to physical, and the joy of fast-paced innovation.

The current AusOcean underwater cameras have no routine way to stop biofouling of the camera viewing window, and although in general the readily growing life in the oceans is wonderful, the biofouling creates poor video visibility. Poor visibility from biofouling looks like spots of opaque green on the image, making it difficult or impossible to analyse the local wildlife and left untreated can eventually damage hardware. The approach to stopping biofouling, also known as antifouling, under consideration for my summer internship was to use ultraviolet light to stop microalgae and bacteria forming the first stage of biofouling.

I was excited - knowing next to nothing about ultraviolet light antifouling and building technology for the ocean, so it was time for me to learn and explore this field. Firstly, I set out to define the problem and scope I was looking at with two important features being it has to be low-cost, could be integrated with existing cameras, reliable, and safe for sea animals. I listed out my stakeholders, user needs, and linking system requirements (which I would continue to reflect on and update). It was time to start research. The research in this field, particularly for low-cost anti-fouling, was notably sparse. The two best documented experiments had some aspects fail during testing leading to somewhat inconclusive results (Lam 2014; Piola et al. 2016). Not that this was the point of my research, but it appeared that there was a significant gap in this area. The research still allowed me to define some key information including most efficient wavelength to use, required light irradiance, approximate cost, safety, and design life. Other antifouling methods were considered, however, due to the user needs it was determined UV antifouling was worth attempting to develop.

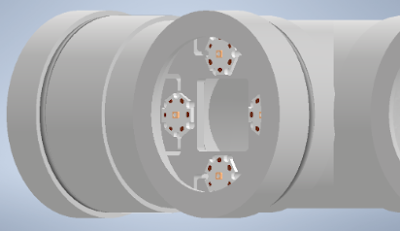

From there, the development of the UV system was done through standard procedures. Test PVC pontoon concept designs were sketched out and one was chosen. Moving toward detailing this design was to create a 3D drawing of the pontoon, and LED mount (Figure 2). Several calculations were performed including test pontoon’s buoyancy, mass requirement, electrical power consumption, radiant flux of the light at different positions, and luminosity through saltwater and mineral oil. I went on to test some of these theoretical calculations, particularly the UVC radiant flux which I used UVC dosage test cards to test.

The current AusOcean underwater cameras have no routine way to stop biofouling of the camera viewing window, and although in general the readily growing life in the oceans is wonderful, the biofouling creates poor video visibility. Poor visibility from biofouling looks like spots of opaque green on the image, making it difficult or impossible to analyse the local wildlife and left untreated can eventually damage hardware. The approach to stopping biofouling, also known as antifouling, under consideration for my summer internship was to use ultraviolet light to stop microalgae and bacteria forming the first stage of biofouling.

I was excited - knowing next to nothing about ultraviolet light antifouling and building technology for the ocean, so it was time for me to learn and explore this field. Firstly, I set out to define the problem and scope I was looking at with two important features being it has to be low-cost, could be integrated with existing cameras, reliable, and safe for sea animals. I listed out my stakeholders, user needs, and linking system requirements (which I would continue to reflect on and update). It was time to start research. The research in this field, particularly for low-cost anti-fouling, was notably sparse. The two best documented experiments had some aspects fail during testing leading to somewhat inconclusive results (Lam 2014; Piola et al. 2016). Not that this was the point of my research, but it appeared that there was a significant gap in this area. The research still allowed me to define some key information including most efficient wavelength to use, required light irradiance, approximate cost, safety, and design life. Other antifouling methods were considered, however, due to the user needs it was determined UV antifouling was worth attempting to develop.

From there, the development of the UV system was done through standard procedures. Test PVC pontoon concept designs were sketched out and one was chosen. Moving toward detailing this design was to create a 3D drawing of the pontoon, and LED mount (Figure 2). Several calculations were performed including test pontoon’s buoyancy, mass requirement, electrical power consumption, radiant flux of the light at different positions, and luminosity through saltwater and mineral oil. I went on to test some of these theoretical calculations, particularly the UVC radiant flux which I used UVC dosage test cards to test.

Figure 2: Computer aided design of acrylic window and PVC piping containing the UV lights and lights’ mount.

I particularly surprised myself with my initial electrical design, as it was actually functional. I’ve always been a bit skeptical of my abilities in electrical design, and in other projects I’ve pursued I feel I have somewhat avoided the field even though I’m very interested in it. Having now designed and built a system from the ground up that is self-sustaining using batteries and solar panels, and managing to (mostly) not damage any components - I now have a new found enjoyment in electrical design and hands-on aspects such as soldering, and subsystem and component testing. This project also required other technologies I was new to including pipe manufacturing, waterproofing, and software development in Go programming language for Raspberry Pi control.

The design for the testing pontoon I landed on, uses well established methods within AusOcean to create contained and water-proof compartments for electronics. The final testing unit was a mutant looking underwater camera housing that contained three experimentation windows and two control windows (Figure 3). After being tested twice for water ingress issues, and with both tests failing, I decided to use a more stock standard design for the test unit at least initially. Instead, there would be two camera housings, one for experimentation, one for control. This was a time saving reason to start experimentation as soon as possible to establish a base test and results so viability could be more readily decided.

The initial results from the testing are positive, with noticeable antifouling taking place during the first week in the experiment (Figure 4). The next few months will be used to track the growth patterns and looking to find an optimal configuration for the camera housing.

Figure 3: First fabricated UV antifouling test unit, to test multiple UV exposures simultaneously.

From my time during this internship, I now have a deep appreciation and fascination for the oceans, and the life within them. Although feeling alien in the underwater environment, with the infectious love for the marine world that my colleagues have, a nervous alien feeling soon turned into one of wonder. This has made me appreciate the oceans and its life for not only their importance ecologically, but also for the unique perspectives and attributes contained within that are vastly different to my normal existence. I now look forward to snorkeling under jetties and spotting fish rather than being fearful, and understand that with the right precautions, the oceans are a safe place for exploration.

I was able to apply the systems engineering approach and to see almost a complete life cycle of design. From research, user needs, system requirements, and ideation, to the procurement, manufacturing, testing, and deployment - I had the exciting opportunity to independently work through a solution to the biofouling problem on the camera lens. As someone who loves seeing the evolution and continual refinement of design, this was a rewarding process. But it was even more rewarding as I was challenged to move from design into testing, which has shown me how much more can be learnt from physically testing and assembling components. After much checking and double checking and triple checking my design, I assembled and soldered the electrical system, and checked the wiring again against my design and that there were no short circuit instances. Switch it on, and all the lights turned on exactly as expected! Similarly when putting it in the water and checking on it after a week, it was a good feeling to see the design hold up as expected.

Finally, helping the oceans using technology, requires a close relationship between the synthetic and natural world - a relationship that establishes the need for innovation and ingenuity. The team here at AusOcean injects an innovation mindset everyday through their supportive attitude to trying new things and to keep going after failures. Their attitudes towards work and design has made me excited to innovate and hopefully push boundaries towards what is actually possible - beyond what I might initially perceive as possible. I’ve appreciated this experience, and I look forward to what’s next to come from AusOcean.

Figure 4: First check of the UV experiment test window.

References

Lam, A, 2014, ‘Ultraviolet LED Biofouling Mitigation’, California Polytechnic State University.

Piola, R, Salters, B, Grandison, C, Ciacic M & Hietbrink, R 2016, ‘Assessing the use of Low Voltage UV-light Emitting Miniature LEDs for Marine Biofouling Control’, Maritime Division Defence Science and Technology Group, DST-Group-TR-3266.

AusOcean is a not-for-profit ocean research organisation that supports open source practices. Open source approaches to tackling environmental issues means embracing collaborative tools and workflows which enables processes and progress to be fully transparent. A critical aspect of working open is sharing data not only with your immediate team but with others across the world who can learn, adapt and contribute to collective research. By contributing to, and supporting open practices within the scientific community, we can accelerate research and encourage transparency. All tech assembly guides can be found at https://www.ausocean.org/technology

Follow us on Instagram, Facebook or Twitter for more photos, videos and stories.

Comments

Post a Comment